The Impact of Packaging and Wrapping Machines on Operational Costs

Packaging and wrapping machines are essential components of the production process in businesses. The impact of packaging and wrapping machines on operational costs depends on several factors. Factors such as the size of the business, packaging volume, type of machine used, and efficiency determine this impact. The use of these machines has various effects on operational costs. In this blog post, we will examine the effects of packaging and wrapping machines on operational costs.

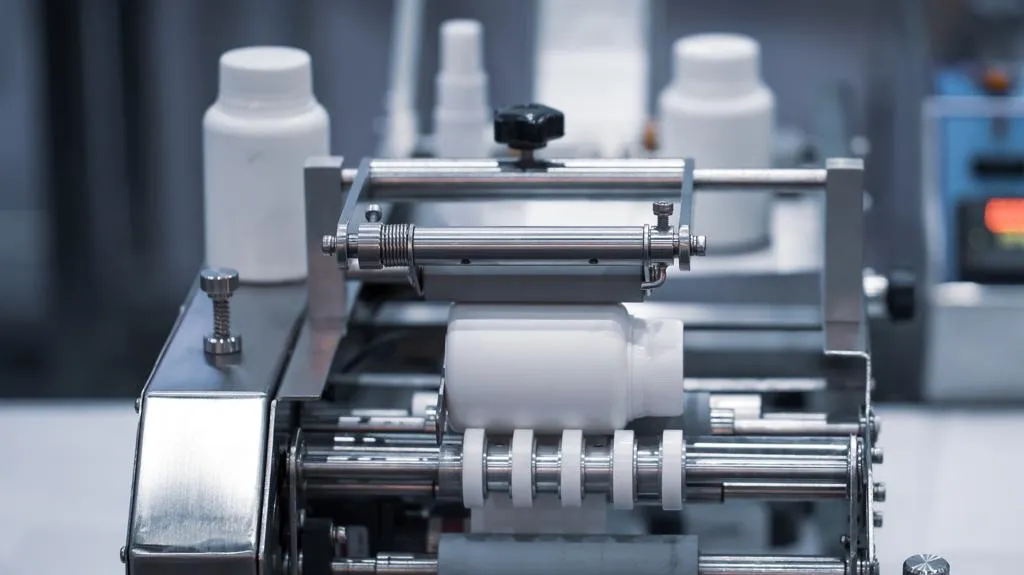

Packaging and wrapping machines can be found in a wide range of options. For example, simple manual packaging machines may be more affordable, while automatic or high-capacity machines may be more expensive. Additionally, the packaging methods of the machines (e.g., vacuum packaging, box sealing, etc.) and their features greatly influence the price.

Some factors that affect the operational costs of packaging and wrapping machines are as follows:

Labor Cost Savings: Automatic or semi-automatic packaging and wrapping machines work faster and more efficiently than manual labor. This significantly saves costs in the business operations. With a decrease in labor requirements, business owners can reduce personnel costs or redirect the workforce to other areas.

Increased Productivity: Packaging and wrapping machines perform packaging processes more quickly and effectively. This leads to increased productivity and allows more products to be packaged in a shorter period. Faster production enables businesses to fulfill more orders and better meet customer demands.

Error Reduction: Packaging errors caused by human mistakes can result in time and resource losses. Packaging and wrapping machines ensure accurate packaging, reducing the costs of repackaging and increasing customer satisfaction.

Material Efficiency: Packaging and wrapping machines minimize material waste. These machines often utilize optimized packaging processes to effectively utilize materials. Less packaging material usage reduces business costs and supports environmental sustainability.

Maintenance Costs: Packaging and wrapping machines are generally long-lasting and require regular maintenance. However, the efficiency and savings provided by the machines balance out the maintenance costs. In the long run, the benefits provided by the machines will outweigh the costs.

In conclusion, packaging and wrapping machines can significantly increase a business's efficiency and profitability. These machines reduce labor costs by enabling products to be packaged quickly and consistently. Moreover, when packaging machines are properly adjusted, they also reduce material waste and make packaging processes more sustainable. This reduces business costs while minimizing environmental impact. Therefore, packaging and wrapping machines have a positive impact on operational costs.https://ayaydinmakine.com/tr/paketleme-makinasi